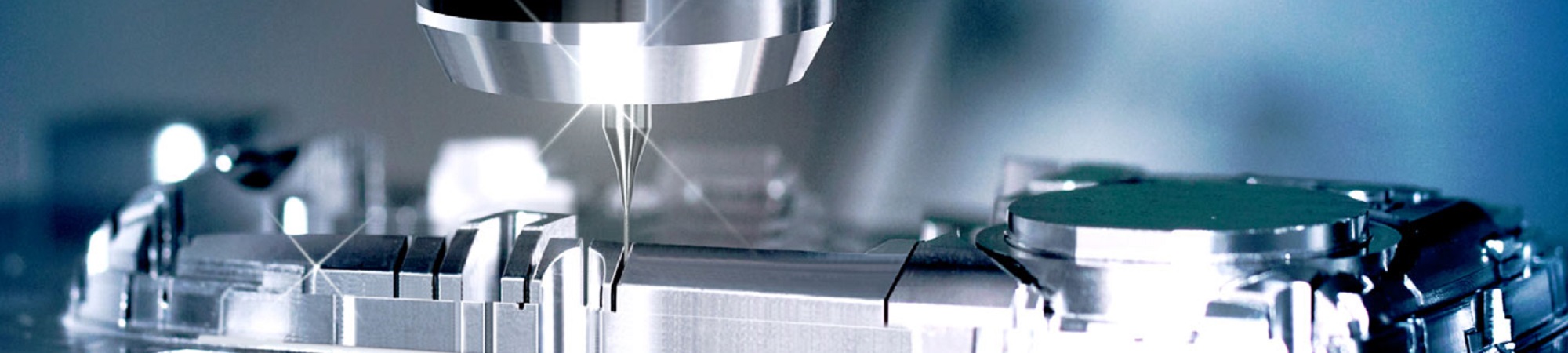

As the factory’s business continues to expand, customer demand also increases. After CNC machining and come to surface finish stage, many customers need to laser print serial numbers, part’s information, or LOGO. In the past, SYD Precision was using CNC machines to engrave, it needs very high spindle speed and small-diameter cutters, or outsourced third-party laser engraving service. Engraving with CNC machine tools is time-consuming and has poor results. At the same time, the very high spindle speed causes great wear to the machine’s spindle. So the best solution is to use fiber laser engraver.

In recent years, with the popularity of laser light sources, the price of the fiber laser engravers have dropped, making it possible for small factories to purchase mid-to-high-end fiber laser engraving machines. After comparing many brands and laser light sources, as well as new features of the new generation products, we purchased a 60W JPT M7 MOPA laser engraver. And equipped with the following optical lenses:

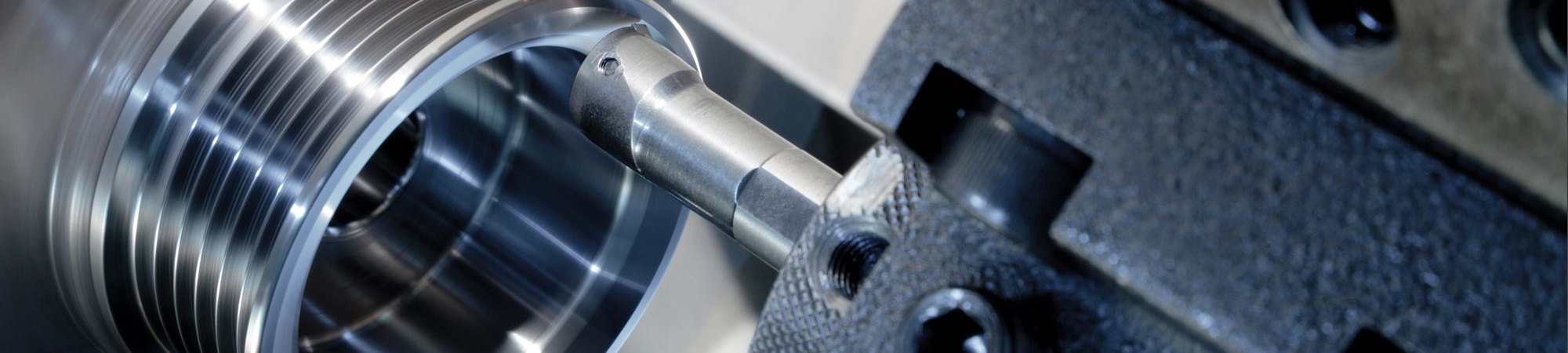

- 70x70mm FL100mm, short focal length, very high power output, specially used for cutting thin sheet parts with thickness of 0.2mm-0.6mm, such as aluminum, stainless steel and copper, etc.

- 110x110mm FL160mm, medium-short focal length, high power output, used for engraving parts with deep depth requirement.

- 175x175mm FL254mm, medium focal length, general power output, daily work lens, can engrave most parts.

- 300x300mm FL420mm, long focal length, low power, mainly used for engraving large workpieces.

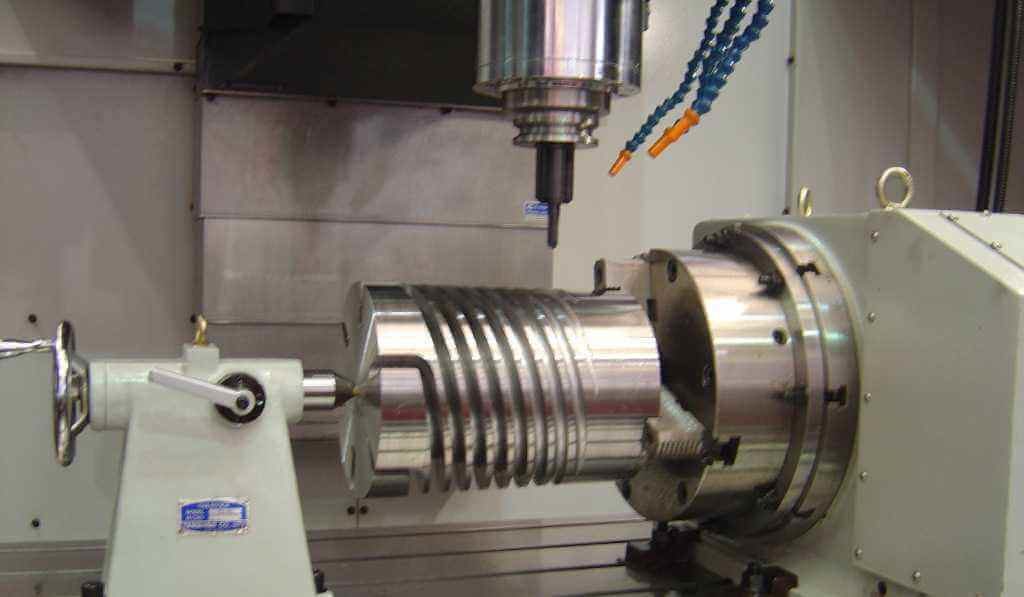

The software for fiber laser machines includes free EzCad2 by China, and paid LightBurn by USA. As a professional machining manufacturer, we chose LightBurn software.

Since purchasing the machine, in less than one month, we have done laser engraving job for four customers. Customer satisfaction has continued to be improved.